Choosing between open cell and closed cell spray foam isn't about which one is "better." It's about which one is right for your specific situation. After 16+ years of insulating homes across Virginia and Maryland, we've learned that the best choice depends on where you're insulating and what you're trying to achieve.

Let's skip the technical jargon and dive into real projects we've completed. These use cases will help you understand exactly when to choose open cell, when to choose closed cell, and why it matters for your home.

Understanding the Basics First

Before we jump into real-world scenarios, here's what you need to know:

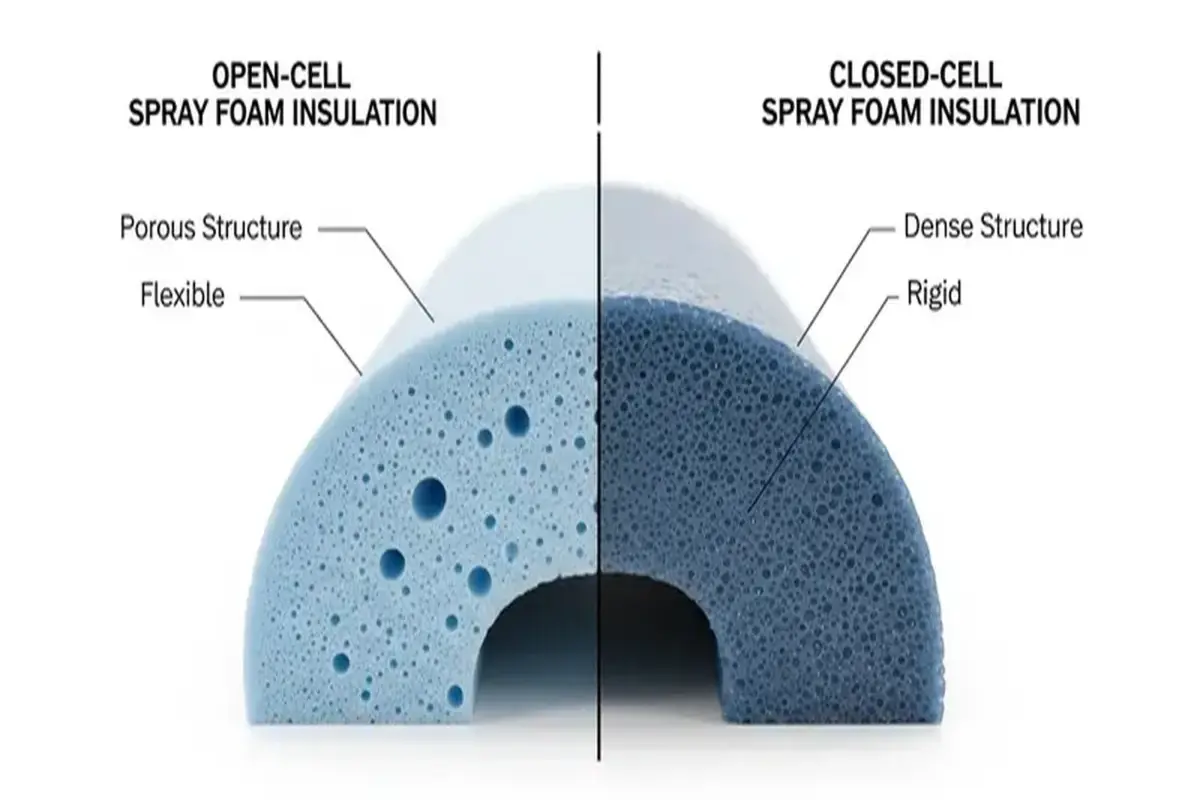

Open Cell Spray Foam:

- R-value of 3.5-4 per inch

- Lighter and less dense

- Allows some vapor transmission

- Excellent sound dampening

- More affordable option

- Expands more during application

Closed Cell Spray Foam:

- R-value of 6.5-7 per inch

- Denser and more rigid

- Acts as a vapor barrier

- Adds structural strength

- Higher upfront cost

- Moisture resistant

Real Use Case #1: Attic Insulation in Herndon, VA

The Situation: A homeowner in Herndon, VA had a traditional vented attic with fiberglass insulation that was failing. Their second-floor bedrooms were unbearably hot in summer and cold in winter.

The Solution: We used open cell spray foam to create an unvented attic system.

Why Open Cell:

- The attic didn't have moisture issues

- Cost savings allowed for thicker application (8-10 inches)

- Superior sound dampening reduced outside noise

- The flexibility handled seasonal wood movement better

The Results: Energy bills dropped 40%, and the second floor became comfortable year-round. The homeowner also noticed significantly less street noise in their bedroom.

Real Use Case #2: Basement Walls in Arlington, VA

The Situation: An Arlington, VA homeowner wanted to finish their basement but was concerned about moisture coming through the concrete walls.

The Solution: We installed closed cell spray foam directly on the concrete foundation walls.

Why Closed Cell:

- Acts as both insulation and vapor barrier

- Won't absorb moisture from concrete

- Adds structural rigidity to older foundation walls

- Higher R-value per inch (important with limited space)

- Prevents water vapor transmission

The Results: The basement stayed dry, warm, and comfortable. No musty smell, no moisture issues, and the space became fully livable year-round.

Real Use Case #3: Crawl Space in Fairfax, VA

The Situation: A Fairfax, VA home had a vented crawl space with falling fiberglass insulation, high humidity levels, and cold floors in winter.

The Solution: We sealed the crawl space vents and applied closed cell spray foam to the foundation walls and rim joists.

Why Closed Cell:

- Crawl spaces are prone to moisture and flooding

- Closed cell won't absorb water if flooding occurs

- Creates a complete moisture barrier

- Prevents ground moisture from entering the home

- More durable in high-humidity environments

The Results: Crawl space humidity dropped from 70% to below 50%, floors became noticeably warmer, and the home's overall energy efficiency improved by 25%.

Real Use Case #4: Cathedral Ceiling in Bethesda, MD

The Situation: A Bethesda, MD home with vaulted ceilings had no space for traditional insulation between the roof deck and drywall.

The Solution: We applied closed cell spray foam directly to the underside of the roof deck.

Why Closed Cell:

- Maximum R-value in minimal space (critical for thin cathedral ceilings)

- No need for additional vapor barrier

- Creates unvented roof assembly (required by code in this application)

- Prevents ice damming in winter

The Results: The great room with cathedral ceilings became comfortable and energy efficient. No more ice dams in winter, and the HVAC system could finally keep up with the space.

Real Use Case #5: Bonus Room Above Garage in Rockville, MD

The Situation: A Rockville, MD homeowner wanted to convert their bonus room above the garage into a comfortable bedroom, but it was always too hot or too cold.

The Solution: We used open cell spray foam in the floor joists (between the bonus room and garage) and in the exterior walls.

Why Open Cell:

- Excellent sound dampening to reduce garage noise

- More budget-friendly for large square footage

- No moisture concerns in this application

- The garage below wasn't conditioned space

The Results: The bonus room became a comfortable bedroom with minimal noise transfer from the garage below. Energy costs for heating and cooling the space decreased significantly.

Real Use Case #6: Rim Joists in Alexandria, VA

The Situation: An Alexandria, VA homeowner had drafty floors and high energy bills despite having attic and wall insulation.

The Solution: We identified the rim joists (the perimeter of the basement ceiling) as the major source of air leakage and applied closed cell spray foam.

Why Closed Cell:

- Rim joists are prone to moisture and air leaks

- Need maximum R-value in limited space

- Creates complete air and moisture seal

- Common area for condensation problems

The Results: Drafts disappeared, floors became warmer, and energy bills dropped 15-20% just from sealing this one critical area.

Real Use Case #7: Metal Building in Manassas, VA

The Situation: A Manassas, VA business owner had a metal workshop with severe condensation problems and extreme temperature swings.

The Solution: We applied closed cell spray foam directly to the metal panels.

Why Closed Cell:

- Prevents condensation on metal surfaces

- Adds structural rigidity to metal building

- Highest R-value for space-limited applications

- Complete air and vapor barrier in one application

The Results: Condensation problems eliminated, temperature control vastly improved, and the building became comfortable year-round for working.

How to Choose: Quick Decision Guide

Based on our 16+ years of experience, here's a simple guide:

Choose OPEN CELL when:

- Insulating attics (in most cases)

- Sound dampening is important

- Budget is a primary concern

- You have plenty of space for thickness

- Moisture isn't a major concern

- Working in interior walls for soundproofing

Choose CLOSED CELL when:

- Insulating basements or crawl spaces

- Working with concrete or masonry

- Space is limited (need max R-value per inch)

- Moisture barrier is required

- Insulating rim joists

- Cathedral ceilings or unvented roof assemblies

- Metal buildings or structures

- Below-grade applications

The Bottom Line

Both open cell and closed cell spray foam are excellent insulation options, but they excel in different situations. The key is matching the right product to your specific application.

Here at DMV Foam, we've completed thousands of projects across Potomac, Vienna, Falls Church, and throughout the DMV area. We evaluate every project individually to recommend the best solution for your home, budget, and goals.

The real-world use cases above show that there's no one-size-fits-all answer. Your attic might need open cell while your basement needs closed cell. Sometimes, the best solution uses both types in different areas of the same home.

Ready to Discuss Your Insulation Project?

We'll evaluate your specific situation and recommend the right spray foam solution for your home.

Schedule Free Consultation